2011 Eurotech Elite Trofeo B446 SY2

5-Axis or More CNC Lathes

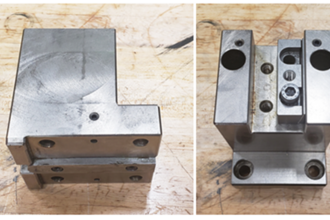

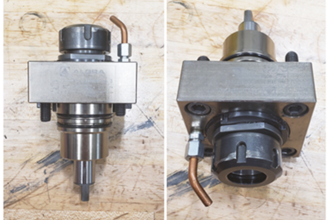

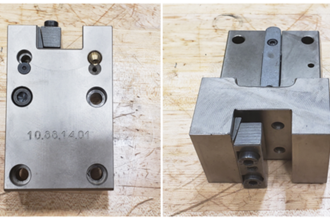

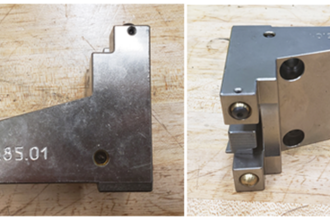

Tool Holder Package

Fanuc Control

C Axis on Both Spindles

Clearshift on the Sub Spindle

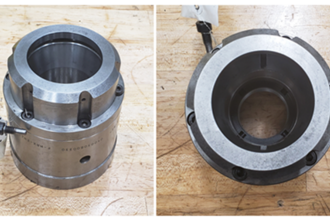

Collet Chucks for the Main and the Sub Spindle

| # Axis | 6 |

| Swing | 20" |

| Chuck Size | 8" |

| Bar Capacity | 2" |

| Power | 20 hp |

| Max RPM | 5,000 RPM |

| Turning Dia | 9.6" |

| Tailstock | No |

MACHINING CAPACITY

Maximum bar capacity................... 2.00”

Maximum turning diameter............................................. 8”

Maximum stroke Y-axis stroke (both) ....................... 3.54”

CHUCK WORK

Chuck diameter - (main spindle)............................. 8”

- (sub-spindle) ............................... 8”

Type..................................................................... hydraulic

Maximum speed ............................................... 5,000 RPM

MAIN SPINDLE

Draw-tube capacity......................... 1.77” (2.00” Optional)

Spindle through bore capacity.................................... 2.17”

Spindle speed range (infinitely variable)................... 5,000

Variable speed steps........................................ Direct drive

Spindle motor (Fanuc 22S)....................................... 20 HP

Motor type .............................................................. S series

Spindle nose ............................................................... A2-5

SUB-SPINDLE

Drawtube capacity.......................... 1.81” (2.05” Optional)

Spindle through bore capacity.................................... 2.17”

Spindle speed range (infinitely variable)................... 5,000

Spindle drive motor (variable speed) max. rating ... 15 HP

Spindle nose ............................................................... A2-5

Slide movement - (B-axis) ................. NC control

Slide stroke - (B-axis) ........................ 26.37”

UPPER TURRET

Number of tool stations (main spindle).......................... 12

Turret indexing time....................................... 0.10 sec/pos.

Turret indexing type ...... Fanuc servo-driven bi-directional

Slide stroke:

Z-axis...................................................................... 24.8”

X-axis ....................................................................... 6.7”

LOWER TURRET

Number of tool stations (main spindle) ..................... 12

Turret indexing time .................................. 0.10 sec/pos.

Turret indexing type . Fanuc servo-driven bi-directional

Slide stroke:

Z-axis............................................................... 21.26”

X-axis................................................................... 6.7”

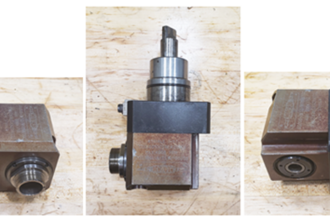

REVOLVING TOOL ATTACHMENT

UPPER/LOWER TURRET

Number of upper turret positions ...................... 12 max

Number of lower turret positions....................... 12 max

Drive motor – maximum rating

(upper and lower turrets) ................................. AC HP 5

Speed range (infinitely variable) ........................... 4000

Revolving tool axis............................. X, C, Z & Y

Y Axis Strokes (both) ..................... +1.97”/ -1.57”

GENERAL INFORMATION

Voltage required ........................... 400 volt AC, 3-phase

Air Supply............................................ 80 psi @ 4 CFM

Amperage Draw............................................. 120 Amp.

MACHINE DIMENSIONS

Width. ................................................................... 85.0”

Height ................................................................... 87.0”

Length with chip conveyor................................. 179.0”

Machine weight with chip conveyor............. 15,874 lbs.

NOTE: Horsepower given are the 30 min. ratings.

EUROTECH FANUC 31i CONTROL

STANDARD FEATURES

FANUC:

- Spindle and axes motors, drives, and

transducers by FANUC

- A.C. spindle and axes motors (Brushless)

- Central unit incl. Pentium processor (32

bits)

- Least input increment : 0.001 mm

- Least command increment: 0.001 mm

- Millimeter data input

- 10.4 LCD graphic display (liquid crystal

display) - low radiation emission

- Electronic hand wheel

- RS 232 interface with connector

- Memory card reader placed near the screen

incl. protection door

PROGRAMMING FUNCTIONS:

- Diameter and millimeter programming

without decimal point

- Constant cutting speed (G96)

- Tool radius compensation (G40-G41-G42)

- Graphic display

- Canned cycle for turning (roughening -

outside/inside finishing - grooves - profile

repetition )

- Canned cycle for drilling (chip breaking and

removal)

- Direct programming using drawing

dimensions and code A (Angle), R (Radius)

and

- C (Chamfer).

- Canned cycle for threading (G76-G78)

- Up to 3 M functions on same Block

- Input of local coordinates G52

- Machine coordinates selection G53 for tool

change position

- Automatic choice of offset value by simply

calling relevant turret position (T6 = T0606)

- Type B Macro instructions, fixed and

changeable variables after turning machine

power off

- Call of sub-programs (M98)

- Call of macro-instructions (G65 - G66)

- Display of actual spindle speed output (even

if program includes G96)

- Table of tool geometry

- Table of offset values for tool wear

compensation with safety (max. input value:

0.999)

- Limit of axes rapid speed (operator panel)

- Display of operator messages in English

- Display of axes and spindle motor power

absorption

EUROTECH OPERATOR PANEL:

- Keyboard featuring an anti-splash

membrane and LED inside

- Machine operational mode change-over

switch

- Spindle rotation speed change-over switch

(override)

- Graduated handle control for axes feed rate

and rapid

- Emergency mushroom switch (red)

- LED indicator for % spindle rpm

- LED indicator for tool position

- 2 position key selector to by-pass safety

mechanisms

- 3 position key selector which acts on use of

operational mode change-over switch

- Cycle start push-button (cycle)

- Hold push-button for spindle axes drive

- Switch to by-pass coolant, also in manual

mode

- Toggle switch for block-by-block operation

- Toggle switch for block skipping

- Toggle switch for optional stop M01

- Switch for inside lightening

- Change-over switch for main or sub-spindle

- Buttons to move “X”, “Z”, “B”, “Y”, “C”

axes

- Dry-run button

- Button for spindle rotation clockwise, in

reverse mode and spindle stop

- Button for chip conveyor (run - stop)

- Button for machine additional lubrication

- Buttons to set turret position and

clockwise/reverse rotation

- Button for spindle collet clamp/unclamp

- Button to operate parts catcher forward

- Button for sub-spindle collet clamp/unclamp

- Button to hydraulically operate tailstock

forward/backward

• SBS Tool Load Monitoring